Tecnotion starts with Togetr Digital Factory

Tecnotion, specialized in the production and customization of high-tech direct drive motors, started the implementation of the Togetr Digital Factory module after a period intensive preparation. Reason for Tecnotion to start this ambitious program is the strategic vision to achieve Operational Excellence and the strong Quality First ambition. Tecnotion is accelerating its growth with expansion of production facilities and growth of its workforce. The Factory Automation program that started last year must fulfill the desire to grow in size as well as to boost quality and efficiency.

Togetr Digital Factory module after a period intensive preparation. Reason for Tecnotion to start this ambitious program is the strategic vision to achieve Operational Excellence and the strong Quality First ambition. Tecnotion is accelerating its growth with expansion of production facilities and growth of its workforce. The Factory Automation program that started last year must fulfill the desire to grow in size as well as to boost quality and efficiency.

Extensive selection process

After an extensive selection process, Tecnotion opted for the Digital Factory module from Togetr. The decisive factor was Togetr's strong focus on the (high-tech) manufacturing industry combined with a software product that covers almost all functional requirements. Jeroen Leus, operations manager at Tecnotion: "Just to get a completely paperless shop floor already provides enough business case. At the moment, a lot of product information and work instructions are still processed on paper. By recording measurements and quality information centrally in the system and applying SPC, we can be much more predictive and thus prevent issues, potential outages and downtime."

"Just to get a completely paperless shop floor

already provides enough business case"

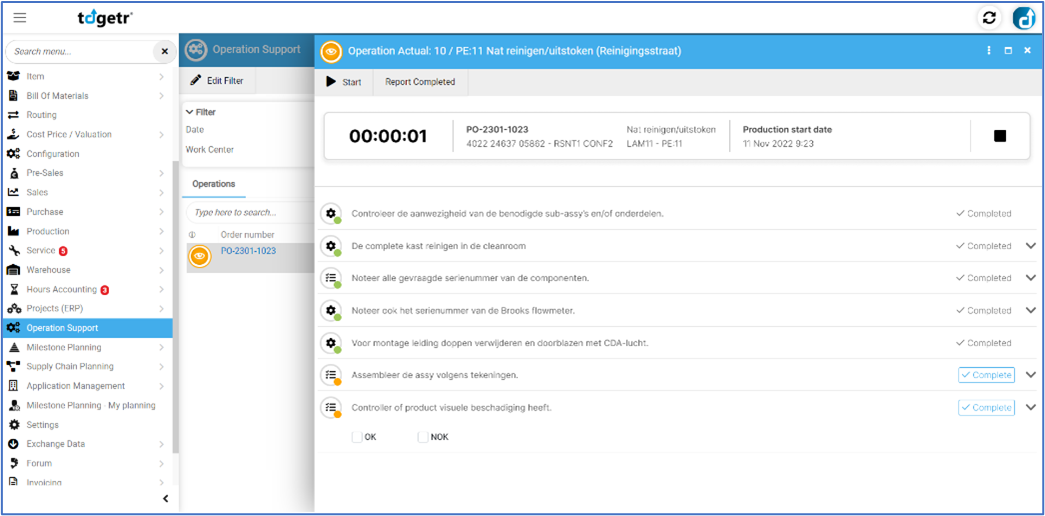

Start with digitization process guidance, work instructions and then follow through

But Tecnotion aims at even more than that. Theo Hoogendoorn adds: "The core of our Digital Factory product is that you start with the digitization of process guidance, micro routings and work instructions. From there you can elaborate the implementation in multiple directions. For example, digitizing tests and measurements based on Test Coverage Documents (TCDs). But linking OCAPs (out of control action plans) is also a very logical one. This allows operators to see more quickly whether or not the production process is under control and can quickly intervene in the event of excessive deviations. Being able to register tickets easily also reinforces the 'closed loop' idea. The product engineers receive faster feedback from the shop floor, which ultimately strengthens the quality".

Togetr Digital Factory visual

Digital Factory 2.0

Togetr is working with customers on Digital Factory 2.0. This makes it possible to generate simple and automated work instructions, process flows and value streams. This is important because in a High Mix-Low Volume environment the series are small and changes are required even during production. With Digital Factory 2.0 the time spent by of process engineers in these dynamics is limited and quality gets the impulse needed. This allows high-tech companies to achieve significant improvements in terms of process flow, quality, yield and lead time. Again an important response to increasing 'upscaling pressure' in the High Tech Industry.

Meer lezen over hoe Togetr SPC in Digital Factories toepast?